04. PLC- Programming Languages

Today, I am going to introduce you to different types of programming languages defined for Programmable Logic Controller (PLC).

These languages are useful for designing and implementing sequential control of the programmable logic in the automation system.

Let’s study, what are those most used and common PLC programming languages.

Different Types of PLC Programming Languages

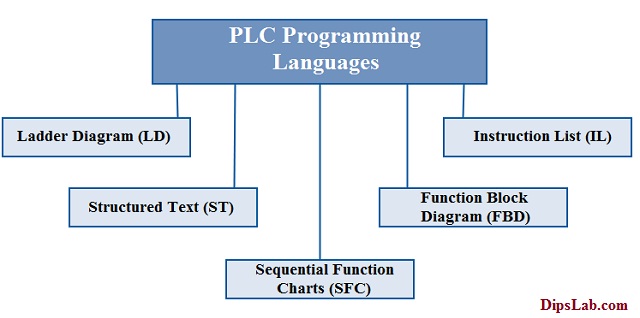

Based on the ‘International Electrotechnical Commission(IEC)‘ standard, PLC programming languages are classified into five main standards.

- Ladder diagram (LD)

- Instruction List (IL)

- Structured Text (ST)

- Function Block Diagram (FBD)

- Sequential Function Charts (SFC)

These languages are accepted internationally. Among all of them, mostly Ladder diagram (LD) programming language is used in the industry.

Let’s dive into each PLC programming Language one by one.

Ladder diagram (LD)

Ladder diagram is the universal programming language of PLC. It has a short abbreviation as LD and also known as Ladder Logic. It is used with programmable logic controllers. And it is one of the oldest programming languages for PLC.

In the ladder diagram, the programming language use to create the program to control the PLC system is known as Ladder Diagram Language or Ladder Logic Language.

Generally, the Ladder Diagram is most popular all over the world (including India). This language is easy to learn by using a logic gate and some important programming rules.

Advantage of Ladder Diagram (LD):

- LD is simple logic construction and more reliable than an electronic circuit controller.

- Easy to learn and read the program.

- Every programming symbol performs specific actions.

- It having good representation for discrete logic.

- Easy to troubleshoot.

- Shut down the power without the switch (i.e. hardware devices).

To learn more about Ladder Diagram, and its basics parts, check this tutorial.

Instruction List (IL)

Instruction List (IL) is another type of PLC programming language. It uses the mnemonic code. So the syntax of this programming language is easy to remember. In general, AB PLC brand works on the Instruction List (IL) programming language.

In an earlier article, I have mentioned different PLC brands and their software. AB PLC is one of the standard PLC brands.

Advantages of IL:

- It has a high execution speed.

- It takes less memory as compared to other programming languages.

Structured Text (ST)

Structured Text PLC language is shortly denoted by the ‘ST’ and ‘STX‘. It uses high-level programming language syntax. The syntax of ST is similar to the syntax of a high-level programming language with loops, variables, conditions, and operators.

Advantages of ST:

- ST is very easier to understand for both novice and experienced programmers.

- Because of its standard coding format, it is easy to edit and modify program written in ST language.

Function Block Diagram (FBD)

Function block diagram (FBD) is a popular and easy way to write a program like a Ladder Diagram. FBD is represented like box which consists of a number of lines of code for putting different programming functions.

It is a graphical language for programming logic controller. So, it makes your job easy to describe a system.

Sequential Function Charts (SFC)

Sequential function charts (SFC) is also a graphical programming language. It is not a textbase. It has become a popular method of accurately specifying sequential control requirements. The benefit of SFC is easy to understand. Because you can visualize what is happening and when it is happening in the procedure of the code.

The main function of SFC is only the active parts of the code are executed. Due to this, it makes easier to troubleshoot and to change the code if problems occur.

Final Thought:

This is all about different types of PLC programming languages commonly used. And you can use those programming languages while developing PLC based on an Automation project.

If you are confused and not sure which programming language you should learn for PLC, go with Ladder Diagram. It is easy to start with a compact PLC or modular PLC.

What’s your experience working on PLC programming? Please share your opinion by comment below.