Variable Frequency Drive (VFD) Working Principles and Uses

What is Variable Frequency Drive (VFD)

VFD is a motor drives, Which has greater functionality and operation capabilities. In addition to adjustable speed control, variable frequency drives offer protections like phase, under, and over-voltage protection. Software and interfacing options of the VFD’s allow the user to control the motors at desired levels.

AC motor speed is controlled in two ways – either by controlling the voltage or frequency. Frequency controlling gives better control due to constant flux density than voltage control. This is where the working of VFDs comes to play. It is a power conversion device that converts the fixed voltage, fixed frequency of the input power to the variable voltage, the variable frequency output to control AC induction motors.

It consists of power electronic devices (like IGBT, MOSFET), high speed central controlling unit (such as a microprocessor, DSP), and optional sensing devices depending on the application used.

Structure of VFDs

The two main features of variable frequency drive are, adjustable speeds and soft start/stop capabilities.

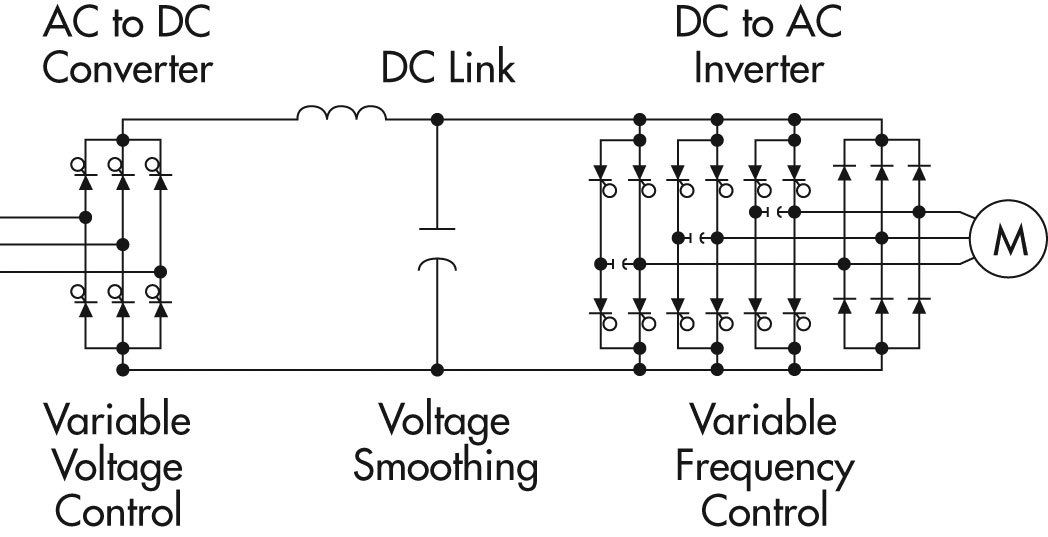

These two features make VFD’s a powerful controller to control the AC motors. VFD consists of mainly four sections; those are rectifier, intermediate DC link, inverter, and controlling circuit.

Rectifier

It is the first stage of a variable frequency drive. It converts AC power fed from mains to DC power. This section can be unidirectional or bidirectional based on the application used like the four-quadrant operation of the motor. It utilizes diodes, SCR’s, transistors, and other electronic switching devices.

If it uses diodes, converted DC power is uncontrolled output while using SCR, DC output power is varied by gate control. A minimum of six diodes are required for the three-phase conversion, so the rectifier unit is considered as six pulse converter.

Inverter

This section comprises of electronic switches like transistors, thyristors, IGBT, etc. It receives DC power from DC link and converts into AC which is delivered to the motor. It uses modulation techniques like pulse width modulation(PWM) to vary output frequency for controlling the speed of induction motor.

Control circuit

It consists of a microprocessor unit and performs various functions like controlling, configuring drive settings, fault conditions, and interfacing communication protocols. It receives a feedback signal from the motor as current speed reference and accordingly regulates the ratio of voltage to frequency to control motor speed.

Working Procedure

The application of VFD is ac motor speed control by cyclo converters.

Power from mains is fed to the rectifier circuit which converts fixed AC to fixed DC. Three leg converters consist of two diodes connected in parallel for each phase, such that one of the diodes conducts when the particular phase is comparatively more positive or negative.

Pulsed DC voltage generated from the rectifier is applied to the DC link circuit. This intermediate circuit comprises inductors and capacitors. It filters the pulsed DC by reducing ripple content and gives DC power a constant level.

To provide variable voltage and variable frequency to the motor, DC power from the DC link should be converted to variable AC by inverter. The inverter consists of IGBTs as switching devices that are controlled by the PWM technique.

Similar to the rectifier circuit, inverter switches also belong to two groups as positive and negative. Positive side IGBT is responsible for the positive pulse and negative side IGBT for a negative pulse at the output of the inverter. So the obtained output is an alternating current which is applied to the motor.

Varying the switching period regulates voltage and frequency simultaneously in the inverter. Modern VFD uses the latest control techniques like a scalar, vector, and direct torque controls, to control the inverter switches in achieving the variable power.

The above figure shows how the voltage and frequency are varied by a variable frequency drive. As an example, AC 480V, 60Hz supply is applied to the VFD which varies the signal voltage and frequency to have control of the speed.

As the frequency is decreased, the speed of the motor also decreases. In the above figure, the average power applied to the motor is decreasing while decreasing both voltage and frequency, provided the ratio of these two parameters is constant.

Benefits of VFD

Variable frequency drives not only offer adjustable speeds for accurate and precise control applications but also have more benefits in terms of process control and conservation of energy. Some of these are given below.

Energy saving

More than 65% of the power is consumed by electric motors in industries. Both magnitude and frequency control technique to vary the speed consumes less power when variable speed is required by the motor. So a great amount of energy is conserved by these VFDs.

Closed-loop controlling

VFD allows accurate positioning of the motor speed by continuously comparing with reference speed even at changes in the loading conditions and input disturbances like voltage fluctuations.

Limits starting current

Induction motor draws current which is 6 to 8 times the nominal current at starting. Compared to conventional starters, VFD’s gives better results because it delivers low frequency at the time of starting. Due to low frequency, the motor draws less current and this current never exceeds its nominal rating at starting as well as operating.

Smooth operation

It offers smooth operations at starting and stopping and also reduces thermal and mechanical stress on motors and belt drives.

High power factor

The inbuilt power factor correction circuit in the DC link of VFD reduces the need for additional power factor correction devices.

The power factor for the induction motor is very low for particularly no-load application, while at full load, it is 0.88 to 0.9. Low power factor results in poor utilization of power due to high reactive losses.

Easy installation

Pre-programmed and factory wired VFDs offer an easy way for connection and maintenance.